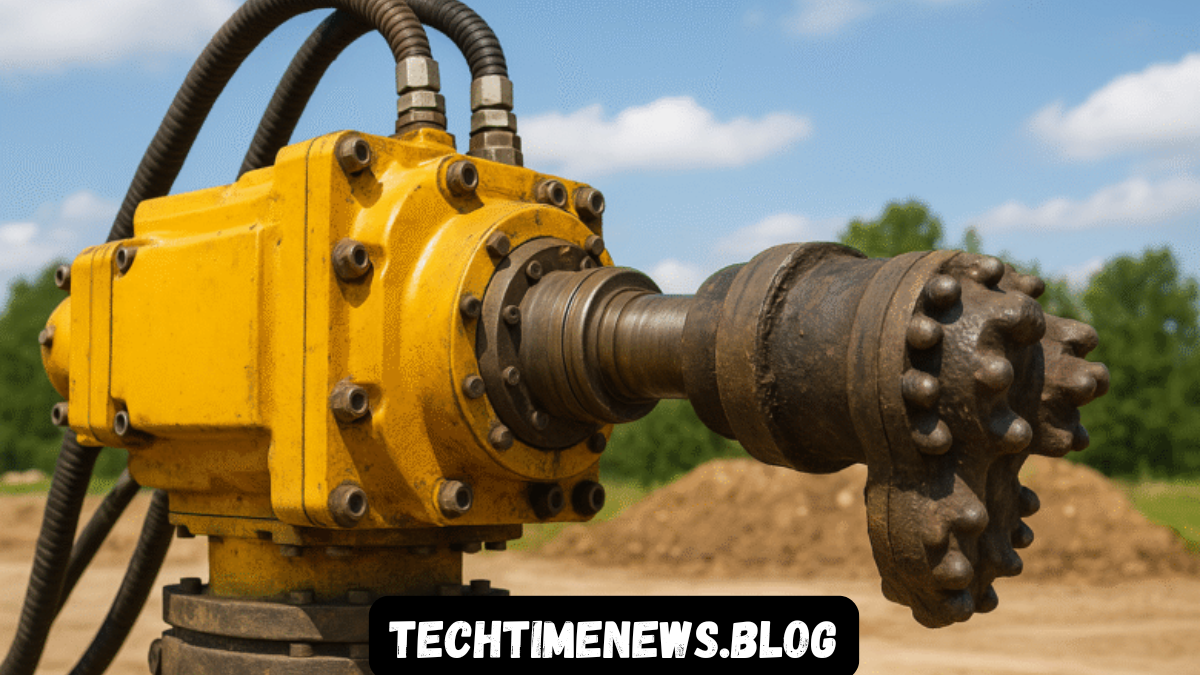

The term “Spezialbohrgetriebe” refers to a special type of gearbox specifically designed for drilling applications These gearboxes are engineered to optimize the performance of drilling machines or systems under particular technical and mechanical requirements. Unlike standard gearboxes that are suitable for a wide variety of uses, Spezialbohrgetriebe are purpose-built to operate under defined conditions such as high torque, low rotational speeds, or unusual drilling angles. The precise alignment of gear ratios, choice of materials, and lubrication systems plays a crucial role in maximizing both performance and service life.

Structural Features and Design

A Spezialbohrgetriebe is constructed to withstand heavy loads and extreme operating conditions. The housing is often made of robust metal alloys that ensure stability while also providing efficient heat dissipation. The gears themselves are typically hardened and precision-machined to achieve high wear resistance. Depending on the intended use, these gearboxes can take various forms such as spur gear, bevel gear, or planetary gear configurations. The choice of design depends on the required gear ratio, available installation space, and types of load to be handled. In some cases, multiple gearbox types are combined to achieve the desired performance characteristics.

Industrial Applications

Spezialbohrgetriebe are used in a broad range of industries. In heavy industry, they are applied in drilling large steel or concrete structures, where massive torque is necessary. In the woodworking industry, they enable precise drilling operations that require constant speed and high repeat accuracy. In oil and gas exploration, Spezialbohrgetriebe play a critical role because drilling underground often involves extreme pressure and temperature conditions. They are also used in aerospace manufacturing, shipbuilding, and in the production of highly precise machine components.

Technological Advancements

Modern Spezialbohrgetriebe have benefited greatly from developments in materials science, manufacturing technology, and electronic control systems. The use of high-strength steels, innovative coatings, and precision CNC machining has allowed for gearboxes that are lighter, more compact, and more efficient than previous generations. Additionally, advanced sensor technologies now allow for real-time monitoring of torque, temperature, and vibration, enabling predictive maintenance strategies. Digital controls can fine-tune both speed and torque to match specific drilling requirements, increasing efficiency and extending service life.

Importance of Gear Ratios

The gear ratio is a critical factor when selecting and designing a Spezialbohrgetriebe. Depending on the application, it may be necessary to convert high rotational speeds into low speeds with high torque, or vice versa. For example, drilling into hard materials like steel or reinforced concrete requires high torque at low speed, whereas softer materials like wood benefit from higher speeds. Achieving the correct gear ratio ensures optimal performance and efficiency for the task at hand.

Maintenance and Longevity

Regular and proper maintenance is essential for maximizing the lifespan of a Spezialbohrgetriebe. This includes replenishing or replacing lubricating oil, inspecting seals and bearings, and checking gear surfaces for wear or damage. High-quality lubricants not only reduce friction but also help dissipate heat. Many modern Spezialbohrgetriebe are designed to be low-maintenance, with sealed housings that prevent dust and dirt ingress. Nevertheless, following a maintenance schedule is important to avoid downtime and ensure operational safety.

Engineering Challenges

Designing a Spezialbohrgetriebe presents several challenges for engineers. In addition to ensuring mechanical strength, they must account for heat buildup during operation. High torque can generate significant heat, leading to material stress and lubrication issues. Vibration and noise reduction are also important, especially in sensitive work environments. Manufacturing precision is critical, as even the smallest deviations in gear geometry can cause excessive wear and performance losses.

Environmental and Sustainability Considerations

In recent years, sustainability has become an important factor in the design and production of Spezialbohrgetriebe. Manufacturers increasingly use recyclable materials and eco-friendly production processes. Energy-efficient gearboxes are being developed to reduce power consumption and lower the overall carbon footprint of industrial operations. Longevity also contributes to sustainability, as fewer replacement parts are needed over time. Some companies are exploring the use of biodegradable lubricants to minimize environmental damage in the event of leaks.

Economic Factors

The cost of acquiring a Spezialbohrgetriebe can vary significantly depending on its size, capabilities, and technical specifications. While standard gearboxes can be mass-produced at lower cost, the production of a custom-designed Spezialbohrgetriebe often requires higher investment. However, these costs are usually offset by greater efficiency, longer lifespan, and reduced downtime. For companies where drilling processes are critical and downtime is expensive, a Spezialbohrgetriebe is often a worthwhile investment.

Future Outlook

The future of Spezialbohrgetriebe will be shaped by continuous technological innovation. The trend is toward more compact, more powerful, and more intelligent systems that can adapt flexibly to different drilling requirements. Artificial intelligence and machine learning could soon play a role in optimizing drilling processes in real time. The use of 3D printing for certain gearbox components may revolutionize manufacturing by enabling complex geometries to be produced Spezialbohrgetriebe faster and at lower cost. New materials such as ultra-light high-performance composites could reduce weight while improving strength.

Conclusion

Spezialbohrgetriebe are indispensable components across many industries where precision and reliability are critical. Their tailored design for drilling applications allows for efficient and safe operation even under extreme conditions. Advances in materials science, manufacturing, and control technology are making these gearboxes more powerful and longer-lasting. With growing demands for efficiency, sustainability, and flexibility, the importance of Spezialbohrgetriebe is likely to increase even further in the coming years.